Improper care can mess your RollPros Blackbird up fast—think misfeeds, paper jams, uneven packing, and in the worst case, total machine failure. The way to think about the Blackbird? So it’s like a high-performance sports car if you want it running smooth and fast, you’ve got to give it regular attention.

The RollPros Blackbird is a revolutionary pre-roll machine designed for high-volume pre roll production. Its precision, reliability, and automation make it a cornerstone of modern dispensary operations, however, its performance is directly tied to how well it’s maintained.

Well-maintained blackbirds also produce higher-quality joints, which lead to better customer experiences, and yes - more brand loyalty, and ultimately more revenue. Regular care reduces waste and ensures that your product meets quality standards batch after batch.

Clean and Reset

Before and after each production cycle:

- Surface cleaning: Wipe down all surfaces with isopropyl alcohol. Focus on resin-prone areas like the loading tray and chute.

- Vacuuming: You can use your handheld vacuum that you already have to remove ground flower and debris from hard-to-reach areas.

- Sensor check: Ensure optical and motion sensors are free from dust and residue for good production.

Regular cleaning helps preserve the mechanical integrity of your machine, prevents buildup that causes jams, and ensures that the next batch starts with a clean slate.

End-of-Day Checklist

- Clear any jammed cones or paper.

- Rewind rolling paper bobbins.

- Recalibrate tray alignment if needed.

- Power cycle the machine to reset diagnostics.

- Empty residue collection areas and bins.

By ending the day with a proper reset, your team reduces the chance of error on the next startup and can catch small issues before they become production-halting problems.

Weekly inspections are your chance to catch issues before they become major problems.

Deep-Clean Focus Areas

- Packing cylinders: Resin builds up quickly. Remove and soak them in alcohol.

- Air hoses and vacuum lines: Blow compressed air through to remove internal debris.

- Motor belts and gears: Inspect for signs of wear or slippage.

Also inspect moving components for friction wear, listen for unusual sounds during operation, and look for any misalignment in trays or funnel guides.

Software and Settings

- Run diagnostic reports.

- Back up your machine settings.

- Update firmware if available from your RollPros Blackbird supplier.

Advanced users can also log error codes from the control panel and review production analytics to optimize fill accuracy and production speed.

Monthly upkeep extends your machine's lifespan and ensures consistent product quality.

System Calibration

- Use calibration weights to test fill accuracy.

- Adjust compaction and vibration settings for different material densities.

- Conduct 10-batch test runs to validate uniform fill levels.

Component Replacement

- Replace O-rings, gaskets, and filters.

- Check cone feed trays for warping.

- Lubricate moving parts with food-grade lubricant.

Recordkeeping

Maintain a log of all replaced parts, issues identified, and actions taken. This helps with warranty validation and troubleshooting.

Keeping an accurate log also helps new operators get up to speed faster and ensures accountability across shifts. A digital spreadsheet or maintenance software can streamline this process.

Proper part management ensures uninterrupted operation.

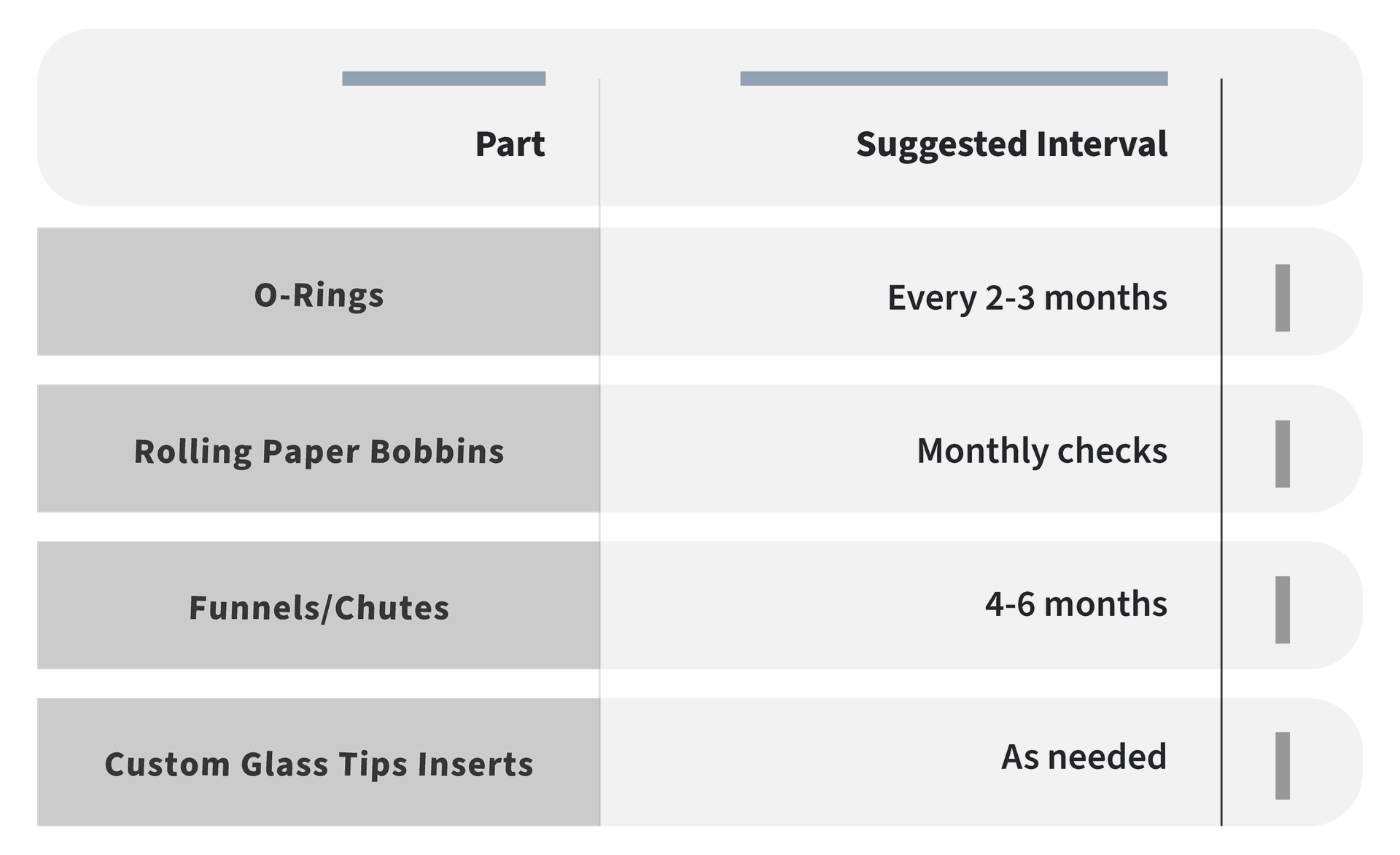

Common Replacement Schedule

| Part | Suggested Interval |

|---|---|

| O-Rings | Every 2-3 months |

| Rolling Paper Bobbins | Monthly checks |

| Funnels/Chutes | 4-6 months |

| Custom Glass Tips Inserts | As needed |

Using authentic parts reduces the risk of breakdowns and ensures safety compliance. Avoid third-party parts not tested with your RollPros Blackbird machine.

Rolling Paper Bobbins for RollPros Blackbird are specifically engineered for optimal tension, alignment, and smooth operation. Generic alternatives often cause tearing or misfeeding, leading to waste and downtime.

Best Practices

- Store bobbins in a clean, dry space.

- Use branded bobbins from a verified RollPros Blackbird supplier.

- Inspect paper consistency and adhesion.

Paper quality can also affect the burning behavior of the pre-roll, so be sure to source paper with consistent grammage and burn rate.

Customization

RollProsSupplies.com offers branded or custom-printed bobbins to reinforce your dispensary brand while ensuring compatibility.

Custom bobbins are not just functional—they're a branding opportunity. Consider holographic foil, QR code integration, or collector designs that resonate with your customer base.

Upgrading to Custom Glass Tips for RollPros Blackbird adds premium value to your pre-rolls. These tips require slight modifications to loading pressure and packing density.

Handling Glass Tips

- Inspect tips for cracks before use.

- Use cones with a compatible taper.

- Adjust packer to apply lighter pressure than with standard paper tips.

Glass tips offer a cleaner, smoother smoking experience and are often favored by connoisseur customers. When introducing them into your workflow, test different sizes and tip shapes to see what yields the best fill quality.

Where to Buy

RollProsSupplies.com offers glass tips made specifically for automated cone machines, reducing the risk of jamming.

All glass tips are stress-tested and optimized for automation, and bulk discounts are available for dispensaries scaling production.

Working with the right supplier can drastically improve your output.

What to Look For

- In-house testing with RollPros Blackbird

- Consistent inventory and fair MOQs

- Custom packaging and private labeling options

- Technical support and documentation access

Recommended Partner

RollProsSupplies.com offers end-to-end solutions including:

- Rolling Paper Bobbins for RollPros Blackbird

- Custom Glass Tips for RollPros Blackbird

- Pre-roll tubes and cones

- Spare part kits

- Direct support and training tools

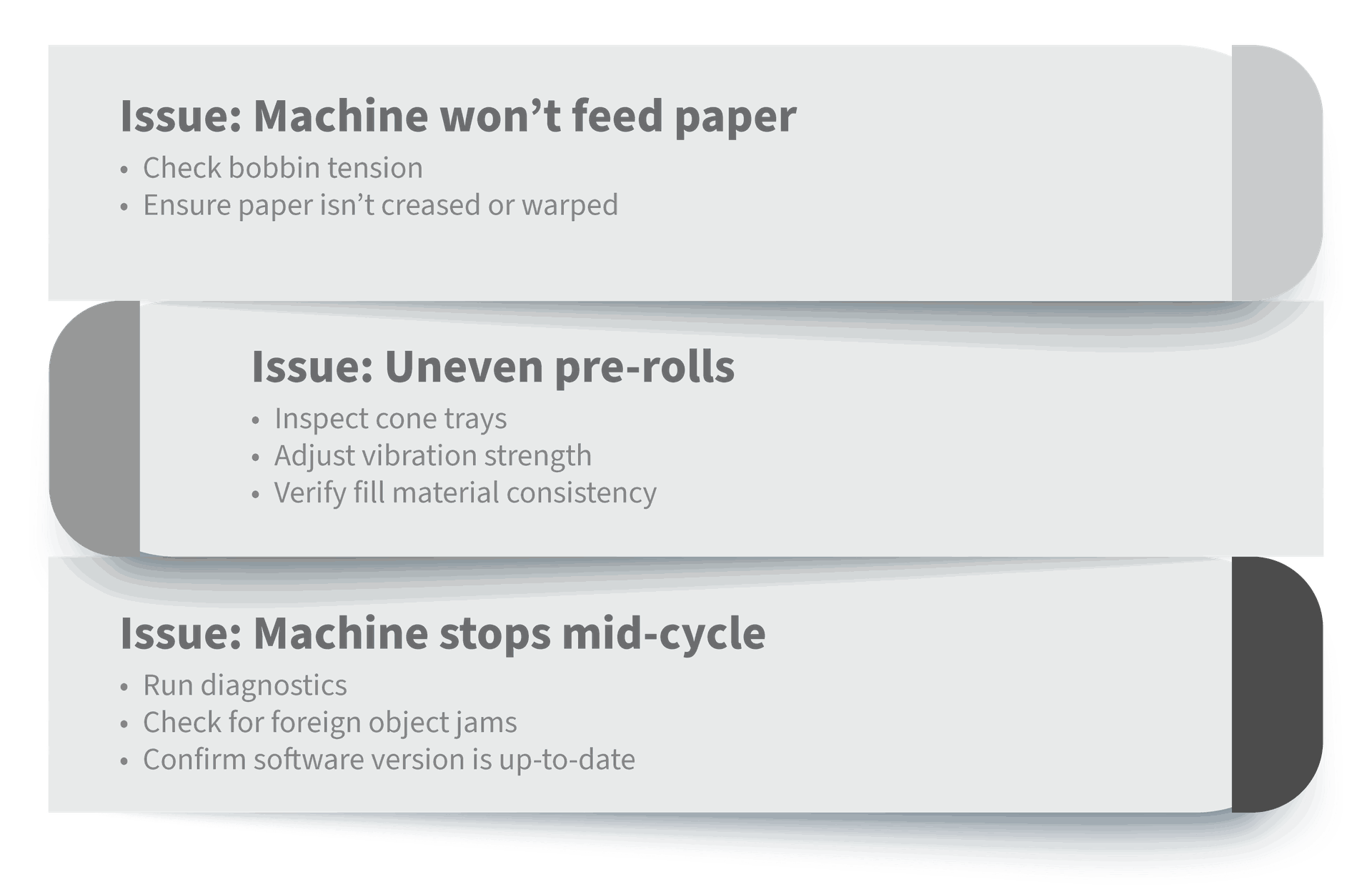

Common Problems and Fixes

Issue: Machine won’t feed paper

- Check bobbin tension

- Ensure paper isn’t creased or warped

Issue: Uneven pre-rolls

- Inspect cone trays

- Adjust vibration strength

- Verify fill material consistency

Issue: Machine stops mid-cycle

- Run diagnostics

- Check for foreign object jams

- Confirm software version is up-to-date

When to Call Support

If multiple issues persist despite regular maintenance, contact your RollPros Blackbird supplier for diagnostics support or repairs.

Some issues may require firmware patches or part replacement. Having a maintenance contract or support line with your supplier ensures you’re never stuck during a rush order.

Taking care of your RollPros Blackbird isn’t just about cleaning; it’s about systemizing care and reducing unplanned interruptions. With routine upkeep, proper supplies, and help from the right RollPros Blackbird supplier, your machine can deliver unmatched consistency and speed for years.

Schedule regular maintenance, train your staff thoroughly, and invest in high-quality supplies that are engineered specifically for your machine. Doing so turns your pre-roll operation into a scalable, dependable revenue engine.

For supplies, parts, and expert consultation, visit RollProsSupplies.com.

Need custom bobbins or glass tips? Reach out to our team and get a tailored quote for your production needs. Let’s keep your Blackbird running like new—every single day.